The UKSW Multidisciplinary Research Center (MCB) recently received an advanced CT scanner. The machine scans items made of any material. If offers precise 3D visualization of their internal structure.

The goal of the UKSW Multidisciplinary Research Center (MCB), recently opened in Dziekanów Leśny near Warsaw, is to develop new technologies to be implemented broadly across the economy, specifically industry and environmental protection. This is also the intention of research involving the CT scanner, which has recently become an important part of MCB’s science and research facilities.

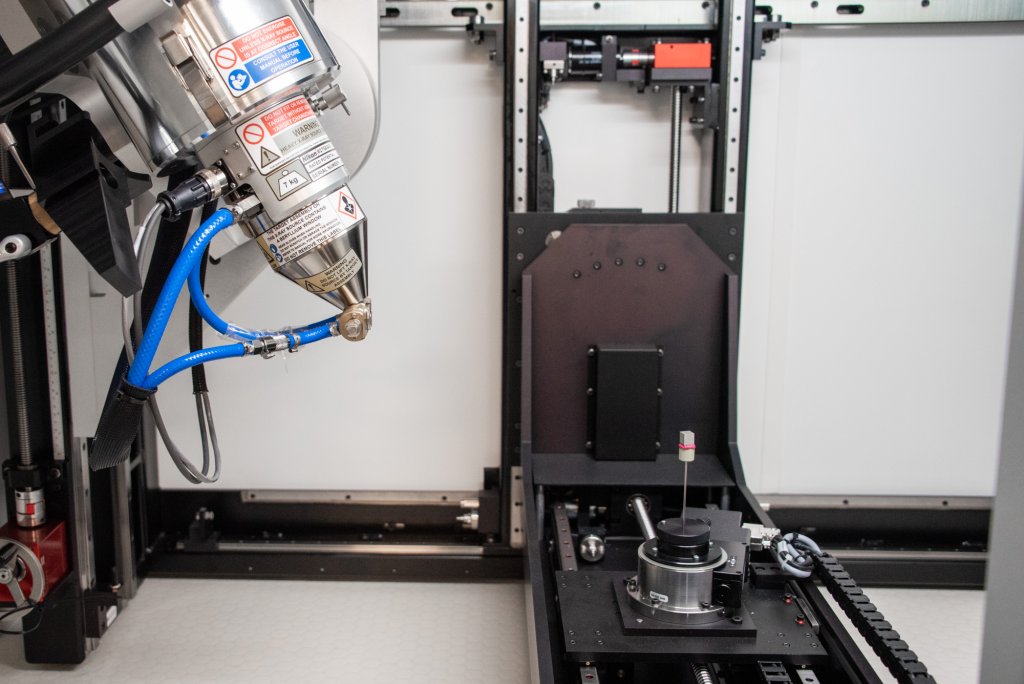

What distinguishes the machine among other similar devices is that it has two lights: a transmission light for micro-scale observations, and a reflective light for object sizes reaching 50 kg.

Capable of detecting any defect

– How does a CT scanner work? First, a beam of X-rays scans an object that rotates around its axis. The scan takes up to several hours and depends on the size, thickness and density of the scanned object, as well as the expected measurement accuracy, Michał Ziętala, MCB technical expert, explains. – The detector will then register the image and the CT 3D Pro Nikon software lets you visualize the shape, together with preliminary processing of the 3D model out of a point cloud. Its function is to process and analyze the target 3D CT image model.

In this process, you can not only visualize the shape and dimensions of the object but also detect micro-cracking, contaminants, porosity of the material which the tested item is made of. This happens irrespective of the material, whether it is metal, ceramics, polymers, composites, or biological materials.

The CT scanner can be used not only to detect any defects but also to identify their character and positioning. This applies to such diverse defects as those found in engine turbines and in electronic components, without disassembling them into parts. The machine lets you view cell structures: porous, openwork, honeycomb, etc. The CT scanner can be used to scan anything and to carry out a precise study without affecting the tested structure.

Revolution in the quality control process

Being able to view metallic or ceramic parts is a revolution in the process of quality control. Without damaging the tested pieces, you can test them, diagnose and modify as necessary. A CT scan helps you understand why the tested piece has worn out early, why it is cracking or corroding, or determine whether the structure of a material is homogeneous. Also, you can discover how a material defect weakened the structure, or find the corrosion sites.

Without the engineering documentation of the tested piece, you can build a 3D model for the purposes of incremental technologies (3D printing) and prepare such documentation. You can also design a 3D model with preset values, print it and examine its structure afterwards. In this way you can find out whether the model print meets the design requirements and whether it has been properly represented during the production process.

– Our CT scanner has a broad range of application, Mr. Ziętala says. – It can be helpful in examining bone pieces and implants, e.g. hip joints. If they are worn out prematurely, we can find out the cause from a CT scan. We can also see the inside of valuable archaeological findings which we do not want to affect or damage.

Pioneering research

But this is still not all. CT scans at MCB are indispensable for studying metal properties in extreme environments.

This is proven by an object prototype made of a titanium/rhenium alloy developed at MCB, with unique strength parameters. The cube, initially in the form of powder, which was produced by a 3D printer for metal, has been placed inside the CT scanner and is being examined.

– Our goal is to develop innovative chemical compositions for copper and silver, titanium and rhenium alloys, says Rev. Marek Muzyk, D.Eng., Director of MCB. – and to do this, we absolutely need the opportunity to examine them with a CT scanner. The initial tests, considering their extraordinary mechanical properties at high temperatures, seem to be promising. The alloys could be used in such fields as aviation, refinery, or the chemical industry.

UKSW is engaged in research on using new MCB-designed materials in the industry, in collaboration with Polish and international corporations and research institutes. MCB is currently engaged in CT scanner research projects together with the Building Research Institute (ITB), the Institute of Materials Engineering and Weaponry Engineering at the Military University of Technology (WAT), as well as businesses such as Orlen, PGE and Timet.

XTH 225ST2X CT scanner from Nikon. Weight: 4200 kg. Dimensions: 2.41m x 1.27m x 2.2m. Weight of the examined object cannot exceed 50 kg. Maximum scan area: 430mm x 430mm. The CT scanner has two sources: reflective and transmission, with maximum power of 225 W and 20 W, respectively. Focal spot size is 3 um at 7W and 225 um at 225 W for the reflective light, and 1 um at 3 W / 20 um at 20 W for the transmission light.

20 January 2023

20 January 2023 Autor: Joanna Herman

Autor: Joanna Herman