Polish scientists, headed by Małgorzata Zaremba, a PhD student at UKSW, discovered the secrets of production of Egyptian faience of two thousand years ago.

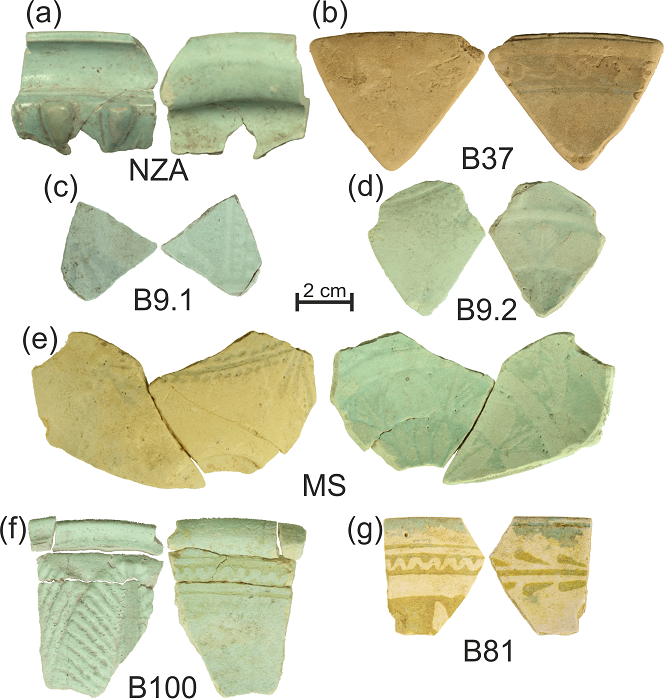

It all started more than a quarter of a century ago at Tell Atrib, a district of Benha, a town in the Nile Delta. During an excavation project, the joint Polish/Egyptian archaeological mission headed by prof. Karol Myśliwiec discovered remnants of craft workshops of the 2nd and 3rd century BC in the Athribis site, 50 km away from Cairo, famous in the ancient world. The ceramics firing kilns attracted the attention of the scholars, including Fabian Welc, a young student of archaeology taking part in the excavations. Along with the faience figures, amulets and pieces of dishes. At that time, Welc dedicated his PhD dissertation to Egyptian faience findings from the Ptolemy and Roman periods, barely described previously, which he managed to catalog. Could he even suspect at that time that he would offer seven of the fragments of faience dishes he found to his PhD student at UKSW Institute of Archaeology, who would then uncover the ancient faience production technology that had not been examined previously?

A breakthrough discovery

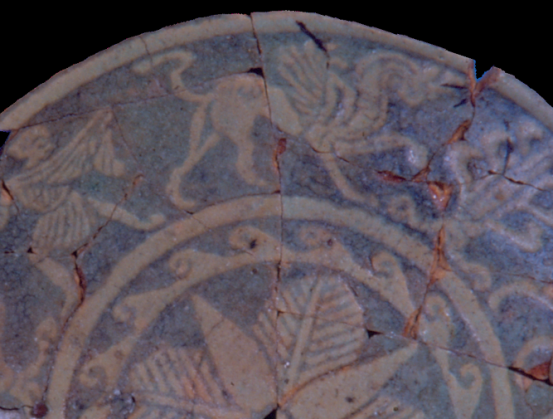

Faience dishes with their sophisticated bas-relief ornaments must have been perceived as luxury goods in ancient Egypt. There must have been a reason why millions of ordinary clay pottery items were found during the excavations conducted for 150 years, whereas of faience dishes there were just a few thousand. They were called “tjehnet” in Egypt. Tjehnet means ‘to shine’. The glazed items with their azure gloss could be associated with lapis lazuli rock but were much less expensive. The faience dish production technique known in Egypt thousands of years ago has not survived. It was effectively forgotten during the initial ages of our era. In Europe, glazing of fired ceramics started in early 15th century in Faenza of Italy – hence the name “faience”. But it was not the same kind of faience as that known in Ptolemaic Egypt…

Only Małgorzata Zaremba, a young graduate of geology, managed to reinstate the extremely complex process of faience dish production step by step. It was a job for a lab researcher and a detective geologist, requiring precision, knowledge and imagination.

– The most complex technology known to the ancient world was successfully recovered. Nobody had made such findings before. This is a breakthrough project, says Fabian Welc, PhD, University professor. – It has given us the opportunity to follow the sequence of events step by step. We now know how the first high-tech ceramics in the history of mankind was created. Huge archaeology centers worldwide were unable to discover that, but Małgorzata Zaremba did it!

Quartz dust from a gold mine

– Contemporary faience has nothing in common with the old Egyptian faience – Małgorzata Zaremba says – it resembles china fired in high temperatures out of kaolin clay and not of quartz!

Having the above mentioned seven pieces of ancient dishes, professional microscopes for archaeometric laboratory testing, excavation log books and inventory records, the young researcher and her team determined the following: the faience dishes were made 90% of quartz dust. Quartz reefs in Egypt are only present in the mountains, in the Eastern Desert. At gold mines! Hence, the material for production of faience dishes could only come from there.

- It was previously suspected that the source of material for the production of these dishes could be desert sand or crushed quartz boulders. But it turns out that it was quartz dust from burrows formed after the extraction of gold…, Małgorzata Zaremba says.

Researchers have discovered that the lumps of quartz, rich in gold, were crushed in unique cradle mortars imported by the Greeks. The remaining quartz dust would be used for production of dishes. It was floated on the Nile, even 500 km down the river, to the Tell Atrib workshops, the second faience dish production center after Memphis.

– Quartz dust itself is powdery. We were looking for a substance that would give plasticity to silica paste, a texture that would allow for formation of dishes. We discovered that it was beef gelatin. So these two ingredients were found essential, the researcher reports, stating that the methods they used in all the findings included scanning microscopy, chemical analysis and analysis of gases that were produced during the firing process and were trapped in the structure of the material, e.g. in glaze bubbles. The researchers discovered that in addition to quartz dust and gelatin, the paste also contained a blend of quicklime, bone meal, fen soil from the river, and lead sulfide.

Faience lighter than clay

The preparation of molds, glazing and firing was an extremely complicated process.

– Detailed studies confirmed our hypotheses: we have discovered that the dishes were shaped by extrusion of superimposed molds – Małgorzata Zaremba says, adding that the team is now in the process of their reconstruction. – One of them would be filled with silica paste and covered with another. Then the glazing suspension, containing copper and lead antimonate, was applied with a brush, giving the glaze its greenish-blue shade after firing. With the bas-relief ornament recesses filled with dyes containing cobalt, the depth effect was emphasized.

The researchers found that the firing process itself, at a temperature of 1050 to 1150 degrees Celsius, ending with rapid cooling of the dishes, took five to eight hours. The researchers reconstructed one of the kilns located in Tell Atrib. What they created was not ordinary pottery but uniquely attractive works of art, with geometric, plant and figure motives.

- The ingenuity of these ancient craftsmen, producing these sophisticated bowls in extremely high temperatures, was incredible – Małgorzata Zaremba says and adds that the faience dishes were lighter than those made of clay. - Already in 4500 BC were faience beads, figurines and tiles produced in Egypt, at the same time when the first pyramids were built. The technology flourished in the middle of the second millennium BC when wonderfully ornamental luxury dishes were first produced. Prof. Fabian Welc says he had never seen two bowls with identical ornaments. The effects were beyond imagination! And that’s what we managed to read out of these few fragments. Two simple ingredients: quartz dust and gelatin, of which such wonders were created.

The research project entitled “Faience items production technology in Ptolemic Egypt in light of archaeological and archaeometric studies” was executed with NCN Preludium 14 funding, grant no. 2017/27/N/HS3/02464, by a team composed of: Małgorzata Zaremba (project manager), prof. Fabian Welc, PhD hab., and Jerzy Trzciński, PhD.

In May this year, Małgorzata Zaremba received a prestigious Martin Aitken Award for young scientists at the 43. International Symposium on Archaeometry in Lisbon. The poster presenting the findings of the research project, which was shown at the Symposium, was selected among 50 presentations.

13 December 2022

13 December 2022 Autor: Joanna Herman

Autor: Joanna Herman